Комментарии

8

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

diduh

Я езжу на Chrysler 300C (1G)

Кто в курсе где находится блок давления шин супер 2018 год буду благодарен

3 года

IVBelousov

Я езжу на Daewoo Matiz (M100/M150)

(до этого — Skoda Superb Mk3)

ох, спасибо! как раз искал, где стоят гребанные датчики температуры салона…

3 года

DmitryISPB

Я езжу на Mitsubishi Pajero Sport (1G)

Большое спасибо!

5 лет

Subbotniy

Я езжу на Volkswagen Arteon

(до этого — Skoda Superb Mk3)

Спасибо, оч полезная инфа!

6 лет

Serge-saraevod

Я езжу на Skoda Superb Combi (Mk3)

Респект и уважуха! Спасибо большое!

6 лет

Roki-24

Я езжу на Volkswagen Passat Variant (B9)

😲а всё также, тока на В8 есть?

7 лет

anders55

Автор

Я езжу на Skoda Superb Mk3

На b8 есть в elsa, в отличие от шкоды…

7 лет

Roki-24

Я езжу на Volkswagen Passat Variant (B9)

Ссылка на бесплатную онлайн ?

7 лет

Contact us

See also

Find a retailer

Take it for a spin

View monthly payment

Download a brochure

Build your own

Discover our range

Elroq

New Enyaq Coupé

New Enyaq

Fabia Hatch

Scala

Octavia Hatch

Octavia Estate

Superb Hatch

Superb Estate

Kamiq

Karoq

Kodiaq

Used cars

Our used car range

Used car offers and benefits

Used Citigo

Used Fabia

Used Rapid

Used Scala

Used Octavia

Used Superb

Used Yeti

Used Kamiq

Used Karoq

Used Roomster

Used Enyaq

Used Kodiaq

Electric and hybrid

Our Electric & Hybrid vehicles

Electric Car Insurance

Jump into electric

Charging overview

Charging at home

Charging points

OVO Energy offer

Charging costs

Powerpass EV charging partnership

Understanding battery range

Electric car battery guide

MyŠkoda iV App

Battery & Safety

Plug-in hybrid technology

Government grants & benefits

Electric vehicle FAQs

Glossary of key terms

Enyaq video guides

Tips & Tricks

Škoda A-Z Guide

Buy

Ways to buy a Škoda

How to build & order online

How to buy from available stock

How to lease my Škoda

Finance options explained

New car offers

Take it for a spin

Value my car

Purchase car accessories

Discover Škoda

Explore the range

Small & city cars

Hatchbacks

Family cars

Estate cars

Small and compact SUVs

SUVs

Seven-seater cars

vRS & SportLine

4×4 cars

Jump into electric

Škoda Edition trims

Our history

Awards

Škoda UK Motorsport

Škoda Partnerships

Škoda cycling

Reviews

Driver’s Seat Initiative

Škoda and dogs

Simply Clever

Safety

New Drivers

Driven Online

All news

Contact us

Careers

Independent Repairers

Finance and offers

Finance options explained

What is a Personal contract plan (P

What is Contract hire?

What is Hire purchase?

What is Finance lease?

What is Lease purchase?

What is 0% finance?

Motability Scheme

New car offers

Servicing & maintenance offers

Used car offers

Business Contract Hire offers

Owner and service

Your Škoda

Škoda Financial Services portal

How to videos

Škoda Connect

Škoda Connect LITE

MyŠkoda App

Servicing & maintenance offers

Servicing & maintenance

Service plans

Bespoke plans

All-in Service Plan

Enyaq software update

Over-the-air update

Enyaq video guides

Electric car battery technology

Škoda electric insurance

Škoda Insurance

Roadside assistance

Warranty

Get an insurance quote

Accessories & merchandise

Wheels & Tyres

Škoda Charging Accessories

Car Care

WLTP

400L Roof Box Recall

Fleet

Welcome to Škoda Fleet

Electric and hybrid cars

Company car drivers

Company car tax guide

Emergency services

Fleet OVO Energy offer

Powerpass EV charging partnership

Business contract hire offers

Build your own

Explore the range

Fabia

Scala

Octavia

Superb

Kamiq

Karoq

Kodiaq

Enyaq Coupé

Enyaq

Elroq

Request a fleet demo

Driverline services

Request a contract hire quote

Compliance, Integrity, and Privacy

Compliance & Integrity

Privacy statement

Terms of use

Modern slavery act

Gender & ethnicity pay gap reports

Code of conduct

Motor industry code of practice

End of life vehicles

Whistleblower system

Social media content permissions

Environmental policy statement

Škoda UK cookie policy

Disability Confident

Ohme charger Terms and Conditions

Laura3 Third Party Licenses

Skoda Superb 3V 2015-2019. Repair manual, instruction manual. Petrol and diesel engines. Vehicle tuning and maintenance, Engine cooling and interior air conditioning systems, Power supply,

engine management and exhaust systems, electrical equipment, DSG transmission. Error codes list. PDF Free download

- Superb 3 (3V3) 2015 — 2019

- Superb Combi 3 (3V5) 2015 — 2019

To date, Superb III is the largest carrier of Volkswagen’s MQB modular chassis — based on a similar design, a large Skoda Kodiaq and VW Tiguan crossover of the 2nd generation was

designed. The MacPherson strut is mounted on an aluminum subframe at the front, and a multi-link is at the rear. Monroe adjustable dampers are available for an extra charge.

Interior design Superb III is as boring and at the same time «delicious», like the VW Passat. There is

nothing pretentious and defiant here — a laconic design is at the forefront. The architecture of the dashboard and the location of the controls are in the best traditions of German automakers.

Finishing and assembly are on top, except that the plastic in the lower part of the dashboard is harsh, although it looks pliable, and the “climate” buttons lack softness when pressed. Inside,

the third-generation car is more spacious than the previous version, which, by the way, clearly did not suffer from a lack of space.

The new version has wider seats in the first row and a range of longitudinal adjustment of the driver’s seat, more headroom, and the second row is freer due to an increase in the wheelbase by 80

mm, and the interior width by 69 mm (up to 1.52 m). The back is so spacious that you can even cross your legs.

The top-of-the-line Superb III multimedia system with voice control and SmartLink is equipped with an SD card slot, Bluetooth, AUX / USB

connectors for connecting gadgets and a built-in 610-watt Canton audio system with 11 speakers, a digital equalizer and a subwoofer. Thanks to it, you can listen

to music and answer phone calls without being distracted from the ride. For an additional fee, you can get more «advanced» Amundsen and Columbus media systems.

Crash tests of the independent European organization Euro NCAP Superb III was successful, earning 5 stars out of 5 possible. The test results are as follows:

driver and adult passenger protection — 86%, child protection — 86%, pedestrian protection — 71%, safety devices — 76%. The liftback received the highest rating not for “beautiful eyes”: firstly,

it has a fairly strong body, and secondly, it has at its disposal an impressive list of modern equipment, which, depending on the configuration, can include up to 9 airbags.

Superb III is quite extensive and consists entirely of diesel and gasoline TSI turbo engines with direct injection and electronic control. Engines, according to the manufacturer, consume from 5

to 7.1 liters. fuel per 100 km (depending on modification) and whimsical to the quality of gasoline — they prefer the 95th. The real fuel «appetite», judging by the reviews of car owners, is

slightly higher than the passport one.

The range of liftback engines includes 1.4-liter units with a capacity of 125 and 150 hp, as well as a 180-horsepower 1.8-liter engine. — all of them are combined with a six-speed manual

transmission, or with a 7-speed DSG «robot». Top two-liter engines with a return of 220 and 280 hp. are paired only with a six-speed DSG robotic transmission.

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Service

Workshop Manual

Rapid NH 2014 ➤

Supe

rb III 2015 ➤

1,4/92; 110 kW TSI Motor

Engine ID

Edition 10.2016

CZCACZDACZE

A

Service Department. Technical Information

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

List of Workshop Manual Repair Groups

Re

pair Group

00 — Technical data

10 — Removing and installing engine

13 — Crankshaft group

15 — Cylinder head, valve gear

17 — Lubrication

19 — Cooling

21 — Turbocharging/supercharging

24 — Mixture preparation — injection

26 — Exhaust system

28 — Ignition system

Service

Technical information should always be available to the foremen and mechanics, because their

careful

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2017 ŠKODA AUTO a. s. D4B80531426

constant adherence to the instructions is essential to ensure vehicle road-worthiness and

and

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Contents

00 — Technical data .

1 Identification .

1.1 Engine number, engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Safety precautions when working on fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Safety precautions when working on vehicles with a start/stop system . . . . . . . . . . . . . . . . 3

2.3 Safety precautions during road tests in which testing and measuring equipment is used . . 4

2.4 Safety precautions when working on cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Safety precautions when working on ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Cleanliness rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Foreign bodies in the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Cable routing and securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Assembly of radiators and condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 General repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

10 — Removing and installing engine .

1 Removing and installing engine .

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Separate engine and gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3 Attach engine attached to engine and gearbox mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.4 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.1 Assembly overview — assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.2 Removing and installing engine mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3 Removing and installing gearbox mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.4 Removing and installing pendulum support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.5 Support the engine in its installed position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.6 Adjusting the unit mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.7 Check assembly bracket setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

13 — Crankshaft group .

1 Cylinder block (pulley end) .

1.1 Assembly overview — ribbed V-belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.2 Summary of components — sealing flange on the belt pulley side . . . . . . . . . . . . . . . . . . . . 40

1.3 Removing and installing V-ribbed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.4 Removing and installing tensioner pulley for ribbed V-belt . . . . . . . . . . . . . . . . . . . . . . . . 43

1.5 Installing and removing the vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1.6 Removing and installing engine support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

1.7 Replacing crankshaft sealing ring — belt pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.8 Removing and installing the sealing flange on the belt pulley side . . . . . . . . . . . . . . . . . . 50

2 Cylinder block on gearbox side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1 Summary of components — cylinder block on gearbox side . . . . . . . . . . . . . . . . . . . . . . . . 52

2.2 Removing and installing flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.3 Removing and installing sealing flange on gearbox side . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.1 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.2 Replace the needle bearing in the crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.3 Measuring axial play of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Contents i

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

4.1 Assembly overview — piston and conrod .

4.2 Removing and installing the piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.3 Checking piston and cylinder bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.4 Removing and installing oil injection nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

15 — Cylinder head, valve gear .

1 Cylinder head .

1.1 Summary of components — cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

1.2 Summary of components — camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1.3 Removing and installing the cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

1.4 Removing and installing camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1.5 Testing the compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1.6 Testing the combustion chamber for tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2 Toothed belt drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.1 Summary of components — toothed belt guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2.2 Summary of components — toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.3 Removing and installing toothed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

2.4 Test timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.5 Remove the toothed belt from the camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

3 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.1 Assembly overview — valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

3.2 Measuring axial play of camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.3 Removing and installing gasket ring for camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3.4 Removing and installing camshaft control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

3.5 Removing and installing cam adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

3.6 Removing and installing N205 the camshaft adjustment valve 1 . . . . . . . . . . . . . . . . . . . . 188

3.7 Removing and installing camshaft control valve 1 in the exhaust N318 . . . . . . . . . . . . . . 188

3.8 Removing and installing valve stem seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

4 Inlet and exhaust valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.1 Inspect valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.2 Testing valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.3 Valve dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

17 — Lubrication .

1 Sump, oil pump .

1.1 Assembly overview — sump/oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

1.2 Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

1.3 Removing and installing oil sump bottom part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

1.4 Removing and installing oil sump top part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

1.5 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

1.6 Removing and installing oil level and oil temperature sender G266 . . . . . . . . . . . . . . . . . . 205

2 Engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

2.1 Summary of components — engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

2.2 Removing and installing engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

3 Crankcase ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

3.1 Summary of components — crankcase ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

3.2 Removing and installing oil separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

4 Oil filter, oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

4.1 Summary of components — oil filter/oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

4.2 Removing and installing oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

4.3 Removing and installing oil pressure switch for reduced oil pressure F378 . . . . . . . . . . . . 215

4.4 Checking oil pressure and oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

4.5 Removing and installing oil filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

4.6 Removing and installing valve for oil pressure control N428 . . . . . . . . . . . . . . . . . . . . . . . . 219

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

ii Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

19 — Cooling .

1 Cooling system, coolant .

1.1 Connection diagram — coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

1.2 Checking the coolant system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

1.3 Draining and filling up coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

2 Coolant pump, regulation of cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

2.1 Summary of components — coolant pump/thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

2.2 Summary of components — electric coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

2.3 Summary of components — coolant temperature sender . . . . . . . . . . . . . . . . . . . . . . . . . . 234

2.4 Removing and installing electric coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

2.5 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

2.6 Removing and installing thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

2.7 Removing and installing toothed belt pulley for coolant pump . . . . . . . . . . . . . . . . . . . . . . 242

2.8 Removing and installing coolant temperature sender G62 . . . . . . . . . . . . . . . . . . . . . . . . 246

2.9 Removing and installing coolant temperature sender at radiator outlet G83 . . . . . . . . . . 247

3 Coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

3.1 Summary of components — coolant pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

3.2 Removing and installing coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

4 Coolers, radiator, radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

4.1 Assembly overview — radiator/radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

4.2 Summary of components — fan shroud and radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

4.3 Summary of components — radiator blind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

4.4 Removing and installing radiator cowling with radiator fan . . . . . . . . . . . . . . . . . . . . . . . . 257

4.5 Removing and installing radiator fan V7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

4.6 Removing and installing radiator with charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

4.7 Removing and installing radiator blind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

4.8 Removing and installing the radiator blind control motor V544 . . . . . . . . . . . . . . . . . . . . . . 264

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

21 — Turbocharging/supercharging .

1 Exhaust gas turbocharger .

1.1 Summary of components — exhaust gas turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

1.2 Removing and installing exhaust gas turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

1.3 Removing and installing charge pressure regulator V465 . . . . . . . . . . . . . . . . . . . . . . . . . . 277

2 Charge-air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

2.1 Summary of components — charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

2.2 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

2.3 Removing and installing charge pressure sender GX26 . . . . . . . . . . . . . . . . . . . . . . . . . . 286

2.4 Checking the charge-air system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

24 — Mixture preparation — injection .

1 Injection system .

1.1 Installation location overview — fuel injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

1.2 Reduce fuel pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

2 Injection valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

2.1 Assembly overview — fuel rail with injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

2.2 Removing and installing the fuel distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

2.3 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

2.4 Clean injection valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

3 Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.1 Assembly overview — air filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

3.2 Removing and installing air filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

4 Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

4.1 Assembly overview — intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

4.2 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Contents iii

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

4.3 Removing and installing the throttle flap control unit GX3 . . . . . . . . . . . . . . . . . . . . . . . . . . 308

4.4 Clean throttle flap control unit GX3 .

5 Senders and sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

5.1 Removing and installing fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

5.2 Check fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

5.3 Removing and installing intake manifold pressure sender GX9 . . . . . . . . . . . . . . . . . . . . 313

6 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

6.1 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

6.2 Removing and installing engine control unit J623 with protective housing . . . . . . . . . . . . 315

7 High pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

7.1 Summary of components — high pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

7.2 Removing and installing the high pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

7.3 Removing and installing high pressure pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

8 Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

8.1 Summary of components — lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

8.2 Removing and installing Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

26 — Exhaust system .

1 Exhaust pipes/silencers .

1.1 Summary of components- silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

1.2 Separating exhaust pipes, silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

1.3 Removing and installing silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

1.4 Aligning exhaust system free of stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

1.5 Inspecting the exhaust system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

2 Cleansing exhaust emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

2.1 Summary of components — exhaust gas cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

2.2 Removing and installing catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

2.3 Removing and installing the exhaust flap control unit J883 . . . . . . . . . . . . . . . . . . . . . . . . 358

28 — Ignition system .

1 Ignition system .

1.1 Assembly overview — ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

1.2 Removing and installing ignition coils with output stage . . . . . . . . . . . . . . . . . . . . . . . . . . 361

1.3 Removing and installing knock sensor 1 G61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

1.4 Removing and installing Hall sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

1.5 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

iv Contents

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

00 – Technical data

1 Identification

(SRL000984; Edition 10.2016)

⇒ “1.1 Engine number, engine data”, page 1

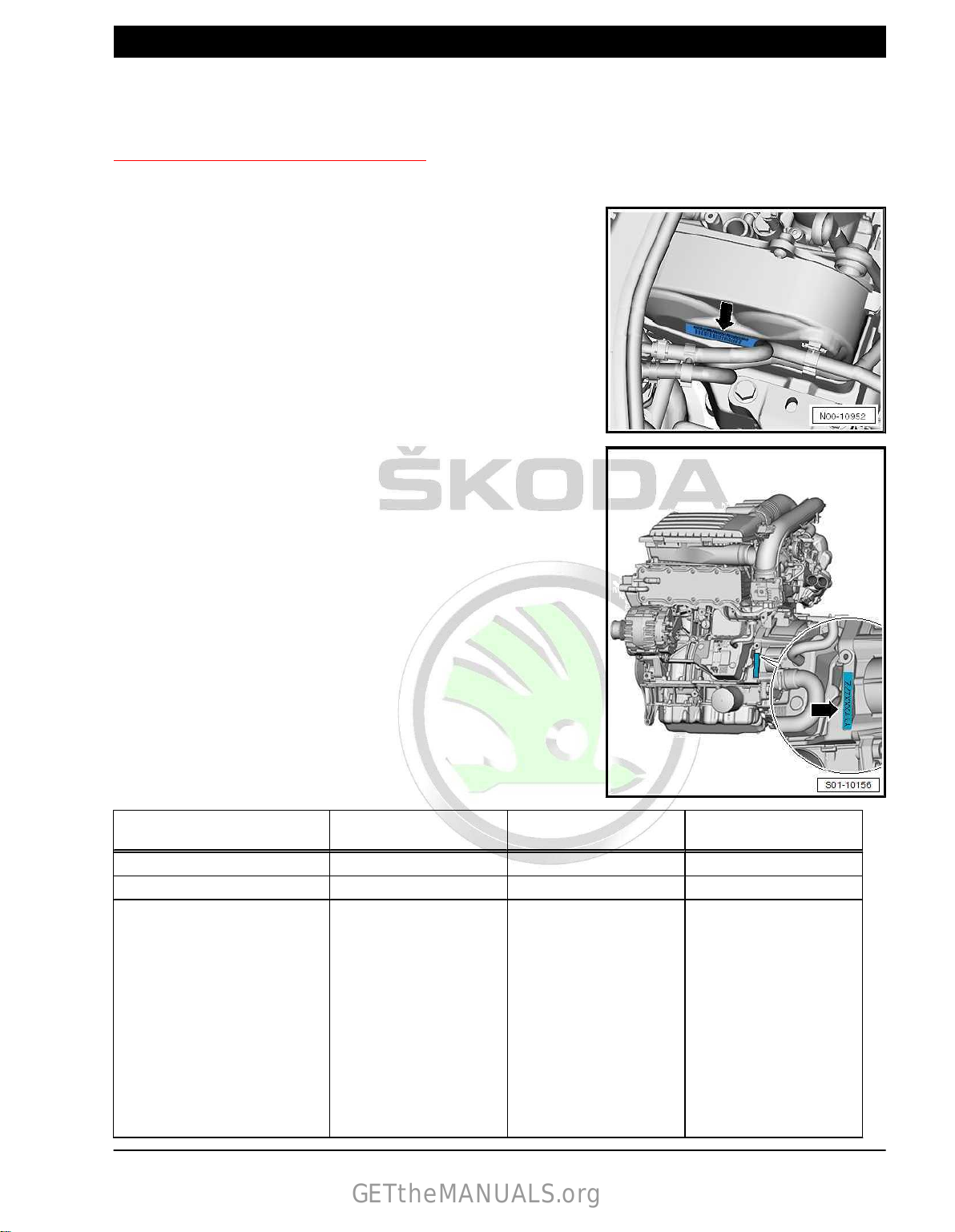

1.1 Engine number, engine data

“The engine identification characters” and the “serial number” are

located on the sticker -arrow-

The “engine identification characters” and “serial number” are lo‐

cated on the cylinder block -arrow-.

The “engine identification characters” are also indicated on the

vehicle data sticker.

♦ Starting with the letter “C”, new four digit engine codes have

been introduced.

♦ The first 3 digits of the engine identification characters refer to

the displacement and the mechanical construction of the en‐

gine. They are type-punched on the cylinder block including

the serial number.

♦ The 4th digit refers to the output and torque of the engine and

depends upon the engine — J623- control unit.

Fitting locations for vehicle data stickers:

♦ ⇒ Maintenance ; Booklet Superb III

♦ ⇒ Maintenance ; Booklet Kodiaq

at the top timing belt guard.

Engine identification charac‐

ters

Superb III production 06.2015 ► 10.2015 ► 03.2015 ►

Kodiaq production 01.2017 ► 10.2016 ► 01.2017 ►

Emission standards EU6 EU6 EU6

Displacement

Power output kW at

Torque Nm at

Bore ∅ mm 74,5 74,5 74,5

Stroke mm 80,0 80,0 80,0

Compression ratio 10,5 10,5 10,5

Cylinder / valves per cylinder 4/4 4/4 4/4

Fuel — RON min. 95 unleaded 95 unleaded 95 unleaded

cm

rpm

rpm

3

CZCA CZDA CZEA

1395 1395 1395

92/5000-6000 110/5000-6000 110/5000-6000

200/1400-4000 250/1500-3500 250/1500-3500

1. Identification 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Engine identification charac‐

ters

Ignition system/fuel injection Motronic ME 17 Motronic ME 17 Motronic ME 17

Firing order 1-3-4-2 1-3-4-2 1-3-4-2

Exhaust gas recirculation no no no

Balancing shaft module no no no

Intake manifold change-over no no no

Camshaft control valve, inlet /

exhaust

Exhaust gas turbocharger yes yes yes

CZCA CZDA CZEA

yes / no yes / yes yes / yes

2 Rep. gr.00 — Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

2 Safety instructions

⇒ “2.1 Safety precautions when working on fuel supply system”,

page 3

⇒ “2.2 Safety precautions when working on vehicles with a start/

stop system”, page 3

⇒ “2.3 Safety precautions during road tests in which testing and

measuring equipment is used”, page 4

⇒ “2.4 Safety precautions when working on cooling system”, page

4

⇒ “2.5 Safety precautions when working on ignition system”, page

4

⇒ “2.6 General safety instructions”, page 4

2.1 Safety precautions when working on

fuel supply system

Fuel under very high pressure creates a risk of injury.

– Wear protective gloves.

– Wear safety goggles.

– Decrease fuel pressure to residual pressure

⇒ “1.2 Reduce fuel pressure”, page 292 .

Place a clean cloth around the connection point and loosen the

connection point carefully before opening the fuel system.

Leaking fuel creates a fire hazard.

Fuel pump is activated by switching on ignition and via driver door

contact switch. Therefore, if the battery power hasn’t been dis‐

connected, for safety reasons the plug of the fuel delivery unit

must be disconnected, or the fuel pump fuse must be removed

before opening the fuel system.

– Take out fuse for fuel pump control unit — J538- ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

Risk

of damage to the electronic components when disconnecting

the battery.

Only disconnect the battery when the ignition is switched off ⇒

Electrical system; Rep. gr. 27 ; Battery; Disconnecting and con‐

necting battery .

2.2 Safety precautions

hicles with a start/stop system

Risk of injury as a result of automatic engine start in vehicles with

start/stop system.

In vehicles with an activated start-stop system (indicated by a

message in

ically if necessary.

– Ensure that the start-stop system is deactivated when carrying

out work on the vehicle (switch ignition off, if required switch

ignition on again).

the dash panel insert), the engine can start automat‐

when working on ve‐

2. Safety instructions 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

2.3 Safety precautions during road tests in

which testing and measuring equipment

is used

Risk of accident due to deflection

Using testers and measuring instruments during driving operation

creates a risk of deflection.

There is a risk of injury due to insufficient securing of testers and

measuring instruments.

Increased risk of injury from unsecured testers and measuring

instruments must be prevented.

Measuring instruments can turn into dangerous projectiles on air‐

bag activation.

Testers and measuring instruments must always be secured on

the rear

there.

seat using a seat belt and operated by a 2nd person from

2.4 Safety precautions when working on

cooling system

Risk of injury due to hot steams.

– Wear protective gloves.

– Wear safety goggles.

Relieve any possible pressure prior to the repair.

When the engine is warm, the cooling system is under overpres‐

sure.

Hot steam may escape when the compensation bottle is opened.

– Cover the cap of the coolant expansion tank with a cloth and

open carefully.

2.5 Safety precautions when working on ig‐

nition system

Risk of injury due to high voltage.

– Do not touch the ignition system with the engine running or at

start speed.

Risk of damage to injection and ignition system

– Ignition must be switched off before disconnecting and re-

connecting the cables of the fuel injection and the ignition

system as well as of the test equipment.

Switch off ignition before an engine wash.

2.6 General safety instructions

The safety measures for the pressure reduction in the high pres‐

sure system must be observed

⇒ “1.2 Reduce fuel pressure”, page 292 .

Place a clean cleaning cloth around the connection point before

detaching hose connections. Reduce pressure by carefully re‐

moving the hose.

– Do not touch or remove ignition leads with the engine running

or at start speed.

Ignition must be switched off before disconnecting and re-con‐

necting the

well as of the test equipment.

cables of the fuel injection and the ignition system as

4 Rep. gr.00 — Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

If the engine must be operated at start speed without it starting,

as for example, when checking the compression pressure, re‐

move the fuse for the voltage supply of the injection valves and

the ignition coils from the fuse holder ⇒ Current flow diagrams,

Electrical fault finding and Fitting locations.

2. Safety instructions 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

3 Repair instructions

⇒ “3.1 Cleanliness rules”, page 6

⇒ “3.2 Foreign bodies in the engine”, page 6

⇒ “3.3 Contact corrosion”, page 6

⇒ “3.4 Cable routing and securing”, page 6

⇒ “3.5 Assembly of radiators and condensers”, page 7

⇒ “3.6 General repair instructions”, page 7

3.1 Cleanliness rules

Carefully observe the following “rules” for cleanliness when work‐

ing on the fuel supply/injection system:

♦ Thoroughly clean the connection points and their surroundings

before releasing.

♦ Place removed parts on a clean surface and cover. Use lint-

free cloths.

♦ Carefully cover or close opened components if the repair is not

completed immediately.

♦ Only install clean parts: Only unpack replacement parts im‐

mediately prior

stored unwrapped (e.g. in tool boxes etc.).

♦ When the system is open: Do not work with compressed air.

Do not move vehicle.

♦ Ensure that no fuel runs onto the fuel hoses. If happens, clean

the hoses immediately.

♦ Protect electrical plug connections from dirt and moisture and

only connect them when dry.

3.2 Foreign bodies in the engine

To prevent penetration of foreign bodies, open channels of the

inlet connection and exhaust tract must be sealed with suitable

plugs during assembly works on the engine, e.g. from the screw

plug set for engine , e.g. -VAS 6122- .

to fitting. Do not use any parts which have been

3.3 Contact corrosion

The use of unsuitable connection elements causes contact cor‐

rosion (screws, nuts, washers, …).

This is why only connection elements with a special surface coat‐

ings are fitted.

Therefore, the rubber or plastic parts and the adhesives are made

from electrically non-conductive materials.

If there is a question mark about the suitability of parts, generally

use new parts ⇒ Electronic Catalogue of Original Parts “ETKA” .

3.4 Cable routing and securing

Lay lines of all kinds in such a way that the original line guide is

re-established.

♦ Fuel feed lines

♦ Hydraulic lines

♦ Brake fluid lines

♦ Coolant lines

6 Rep. gr.00 — Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

♦ Vacuum lines

♦ Activated charcoal filter system lines

♦ Electrical lines

To rule out mix ups and ensure the original fitting position, mark

the lines before disassembly.

Make photos or sketches where necessary.

To avoid damage to lines, ensure sufficient clearance from all

moving or hot components.

Insulation or heat shield matts must be installed again in their

original position.

Secure all hose connections with hose clamps, assignment⇒

Electronic Catalogue of Original Parts .

When installing fit the coolant hoses free of stress, without them

touching any other components (pay attention to the marking on

the coolant connection and hose).

3.5 Assembly of radiators and condensers

The radiator, condenser and charge air cooler may have minor

indentations on

case of damage. Radiator, condensers or charge air cooler must

not be replaced because of these indentations.

the fins, even if assembly is correct. This is not a

3.6 General repair instructions

⇒ “3.6.1 Additional instructions when undertaking assembly work

on the air-conditioning system”, page 7

⇒ “3.6.2 General instructions for charge air system”, page 8

⇒ “3.6.3 General notes on the ignition system”, page 8

⇒ “3.6.4 General notes on the injection system”, page 9

3.6.1 Additional instructions when undertak‐

ing assembly work on the air-condition‐

ing system

CAUTION

Risk of frost due to refrigerant.

Do not open the refrigerant circuit of the air conditioning system.

In order to avoid damage to the condenser as well as to the re‐

frigerant lines

over-tensioned, kinked or bent.

Steps which should be taken in order to remove and install the

engine without opening the refrigerant circuit

– Remove the holding clamp(s) of the coolant lines.

– Removing AC compressor ⇒ Heating, Air Conditioning; Rep.

gr. 87 ; AC compressor; installing and removing AC compres‐

sor .

– Mount the AC compressor in such a way that the refrigerant

lines/hoses are not under tension.

and hoses, ensure that the lines and hoses are not

3. Repair instructions 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

3.6.2 General instructions for charge air sys‐

tem

When undertaking all installation work, particularly in the engine

compartment because of its cramped construction, please ob‐

serve the following:

♦ Lay lines of all kinds (for example, for fuel, hydraulic fluid,

cooling fluid and refrigerant, brake fluid, vacuum) and electri‐

cal lines in such a way that the original line guide is reestablished.

♦ Ensure that there is adequate free access to all moving or hot

components.

In case a mechanical damage to the exhaust gas turbocharger is

found, for example, damage to the compressor wheel, it is not

sufficient to only replace the turbocharger. In order to avoid con‐

sequential damage, perform the following tasks:

♦ Clean all oil lines.

♦ Change engine oil and oil filter.

♦ Inspect the air filter housing, the air filter element and the in‐

take hoses for contaminations.

♦ Inspect the whole charge-air routing and the charge air cooler

for foreign bodies.

♦ The charge-air system must be tight.

♦ Replace self-locking nuts.

♦ Hose connections and hoses for the charge air system must

be free of oil and grease before being installed.

♦ Only install approved clamps for securing the hose connec‐

tions ⇒ ETKA — Electronic Catalogue of Original Parts .

♦ Spring-type clip pliers are recommended for installation of

spring-type clips.

♦ Before connecting the oil feed line, fill the exhaust turbocharg‐

er via the connection fitting with engine oil.

♦ To ensure the oil supply to the exhaust gas turbocharger,

leave the

exhaust gas turbocharger.

engine running for about 1 minute after installing the

3.6.3 General notes on the ignition system

♦ Switch off the ignition before disconnecting and connecting the

battery, as this may damage the engine control unit.

♦ The engine control unit and further components are equipped

with self-diagnosis; inspect ⇒ Vehicle diagnostic tester.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the event

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

Safety measures

⇒ “2.5 Safety precautions when working on ignition system”, page

4 .

Setting data, spark plugs:

♦ ⇒ Maintenance ; Booklet Superb III

♦ ⇒ Maintenance ; Booklet Kodiaq

8 Rep. gr.00 — Technical data

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

3.6.4 General notes on the injection system

♦ The engine control unit is equipped with a self-diagnosis sys‐

tem. Before repairs and also for fault finding, first of all inter‐

rogate the event memory. Also check the vacuum hoses and

connections (unmetered air).

♦ Fuel hoses in the engine compartment must only be secured

with spring clips ⇒ ETKA — Electronic catalogue of original

parts . The use of clamp-type or screw-type clips is not al‐

lowed.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Do not use sealants containing silicone. Traces of silicone el‐

ements drawn

damage the lambda probe.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the event

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

Safety precautions when working on the injection system

⇒ “2.6 General safety instructions”, page 4 .

in by the engine are not burnt in the engine and

3. Repair instructions 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

10 – Removing and installing engine

1 Removing and installing engine

⇒ “1.1 Removing engine”, page 10

⇒ “1.2 Separate engine and gearbox”, page 19

⇒ “1.3 Attach engine attached to engine and gearbox mount”,

page 20

⇒ “1.4 Installing engine”, page 21

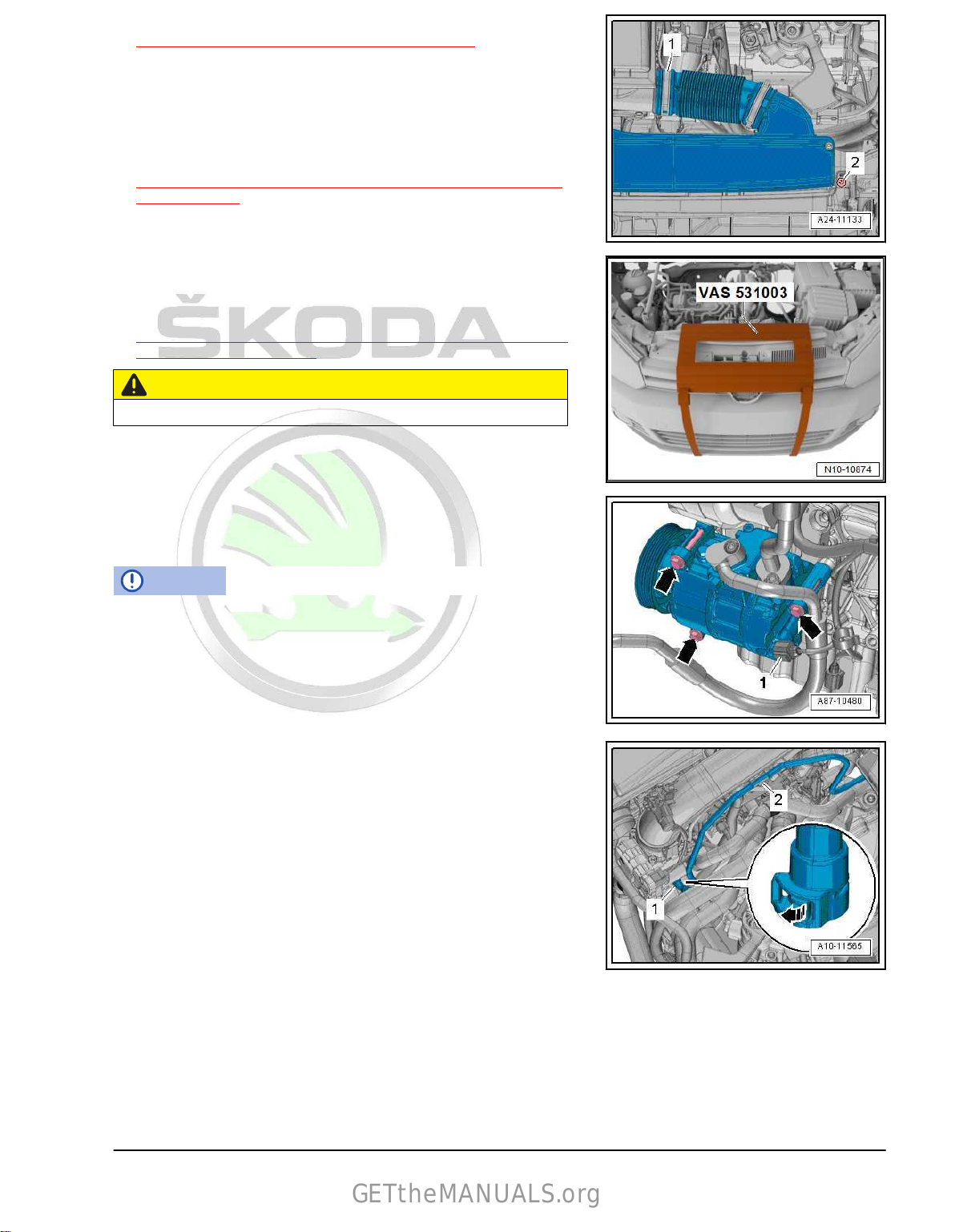

1.1 Removing engine

Special tools and workshop equipment required

♦ Removal tool for inner lining of the door panel — MP8-602/1♦ Extension — 2024 A /1- of lifting device — MP9-201 (2024A)♦ Engine and gearbox jack , e.g. -V.A.G 1383A- or -VAS 6931♦ Engine mount — T10497A♦ Hose strap pliers , e.g. -VAS 6362♦ Locking pin — T10060A♦ Double ladder , e. g. -VAS 5085♦ Protective goggles and gloves

♦ Radiator protection mat — VAS 531003-

Note

♦

The engine is removed downwards together with the gearbox.

♦

All cable straps that have been loosened or cut open when the

engine was removed must be attached again in the same lo‐

cation when the engine is installed again.

♦

Leave the ignition key in the ignition lock so that the steering

lock does not click into place.

– Remove the front wheels ⇒ Chassis, axles, steering; Rep. gr.

44 ; Wheels, tyres .

– Remove the sound dampening system ⇒ General body re‐

pairs, exterior ; Rep. gr. 66 ; Noise insulation; Summary of

components — noise insulation .

– Remove the front left and right wheelhouse liner ⇒ General

body repairs, exterior; Rep. gr. 66 ; Wheelhouse liner; remov‐

ing and installing front wheelhouse liner .

– Remove air filter housing

⇒ “3.2 Removing and installing air filter housing”, page 302 .

WARNING

Fuel under very high pressure creates a risk of injury.

– Reduce the fuel pressure in the high pressure system

⇒ “1.2 Reduce fuel pressure”, page 292 .

10 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

– Drain coolant

⇒ “1.3 Draining and filling up coolant”, page 225 .

– Release screw left and right arrow -2-.

– Unclip and remove the air guide on the lock carrier.

– Remove battery

and battery tray ⇒ Electrical system; Rep. gr.

27 ; Battery; Removing and installing battery .

– Removing fan shroud

⇒ “4.4 Removing and installing radiator cowling with radiator

fan”, page 257 .

– Cover radiator with radiator protection mat — VAS 531003- .

Vehicles with air conditioning

– Remove the ribbed V-belt

⇒ “1.3.2 Removing and installing V-ribbed belt — Vehicles with

air conditioning”, page 42 .

CAUTION

Risk of frost due to refrigerant.

Do not open the refrigerant circuit of the air conditioning system.

– Disconnect plug connection -1- on the control valve for the air

conditioning system compressor — N280- .

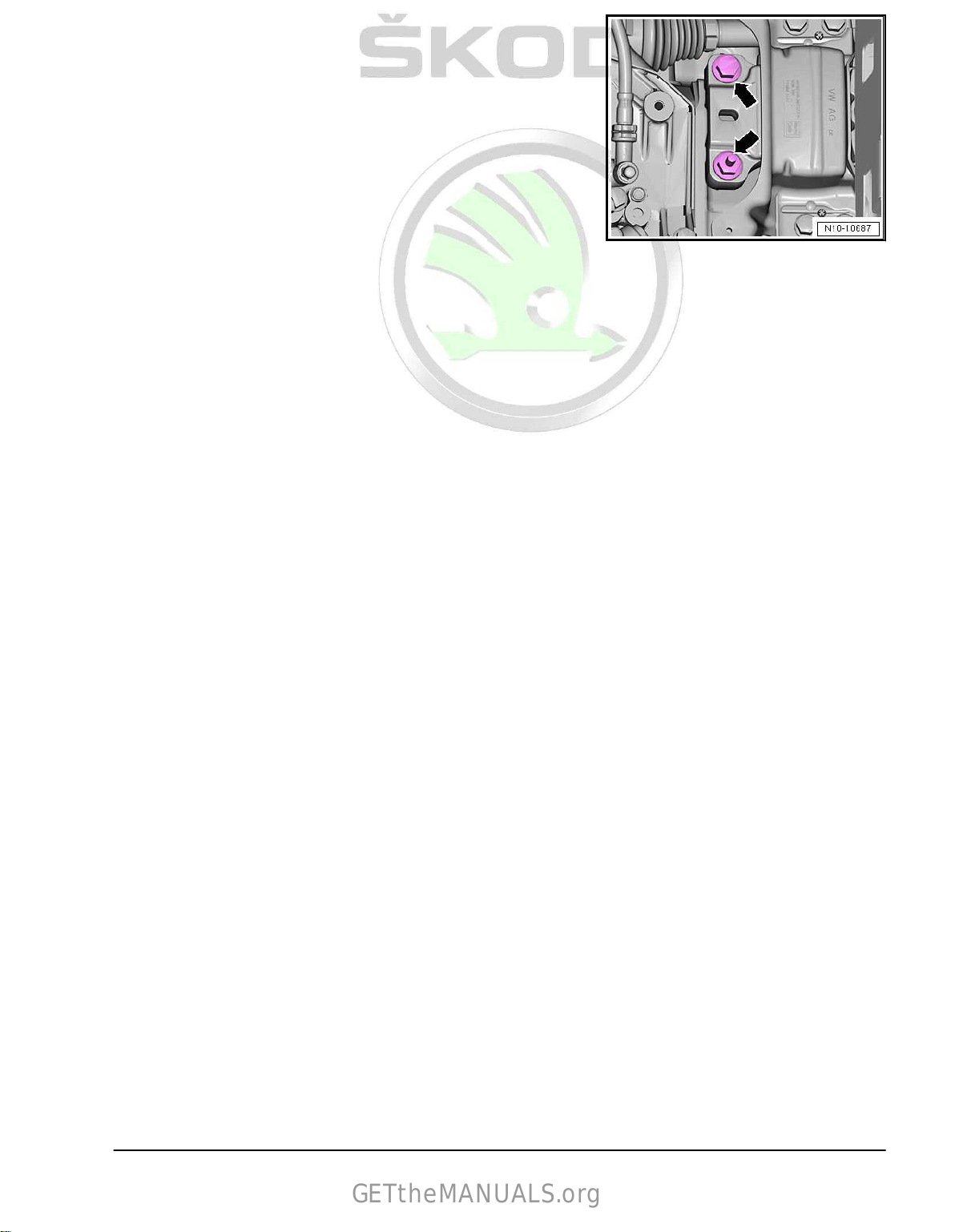

– Release screws -arrows- for AC compressor.

NOTICE

Risk of damaging AC compressor, refrigerant lines and hoses.

♦ Do not over-tension, buckle or bend refrigerant lines and ho‐

ses.

– Remove AC

compressor with connected refrigerant hoses and

strap up to the right side.

Continued for all vehicles

– Unlock catch -arrow- and remove vacuum hose -1-.

– Expose vacuum hose on the air guide pipe -2-.

1. Removing and installing engine 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

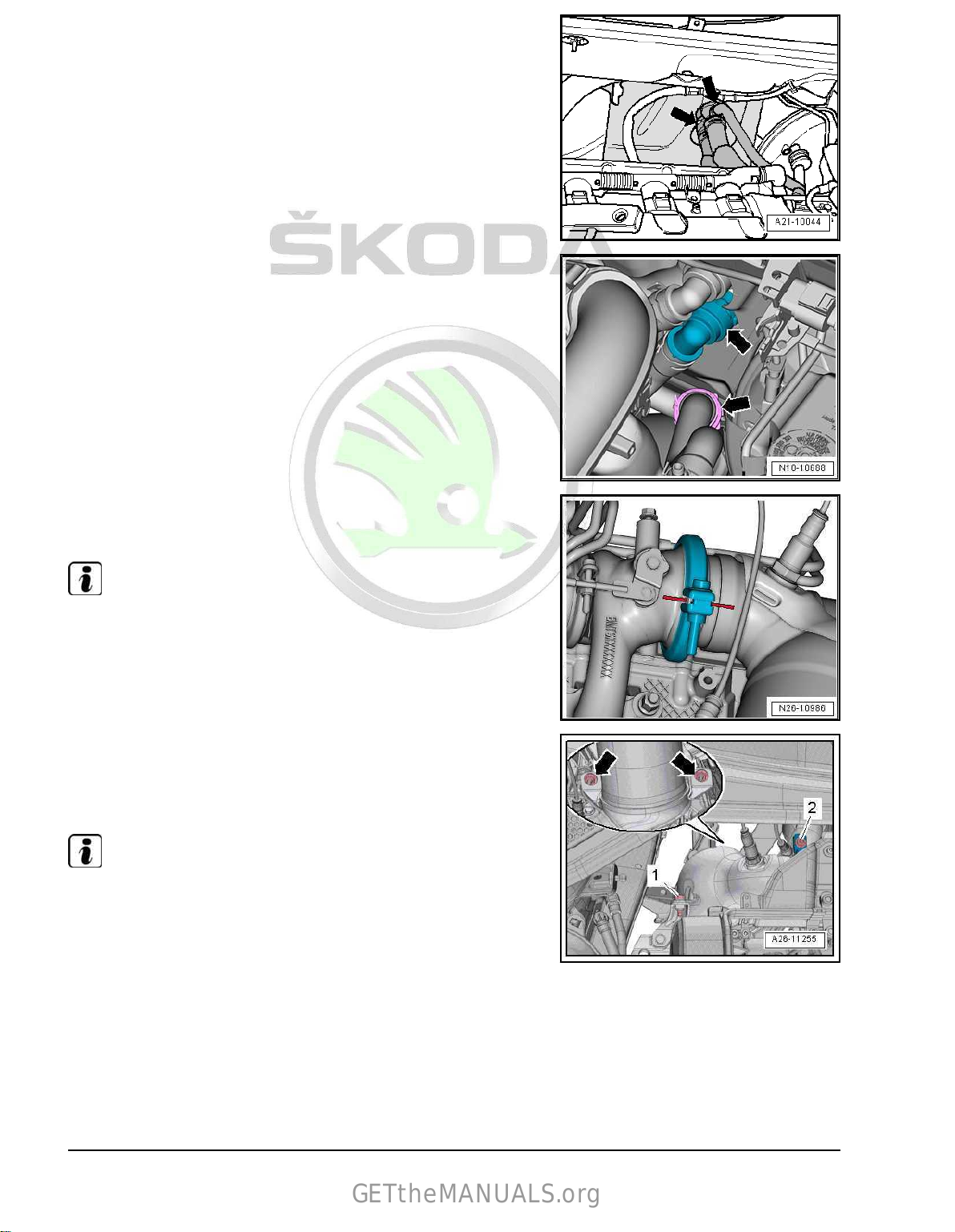

Vehicles without auxiliary heating

– Raise holding clamps -arrows- and remove coolant hoses

from heat exchanger for heating.

Vehicles with auxiliary heating

– Loosen holding clamp and holding clamps and pull off both

coolant hoses -arrows-.

Continued for all vehicles

– Mark the position of the clamp.

Note

♦

Before loosening the separation point between catalytic con‐

verter and turbocharger, mark the position of the clamp.

♦

Put the clamp back into position when assembling!

– Unscrew screw -2- and remove screw clamp.

– Remove screw -1-, remove nuts -arrows- and strap up cata‐

lytic converter to the bodyshell so as not to damage the

decoupling element.

Note

do not twist decoupling element in the exhaust pipe more than

10° — risk of damage

12 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

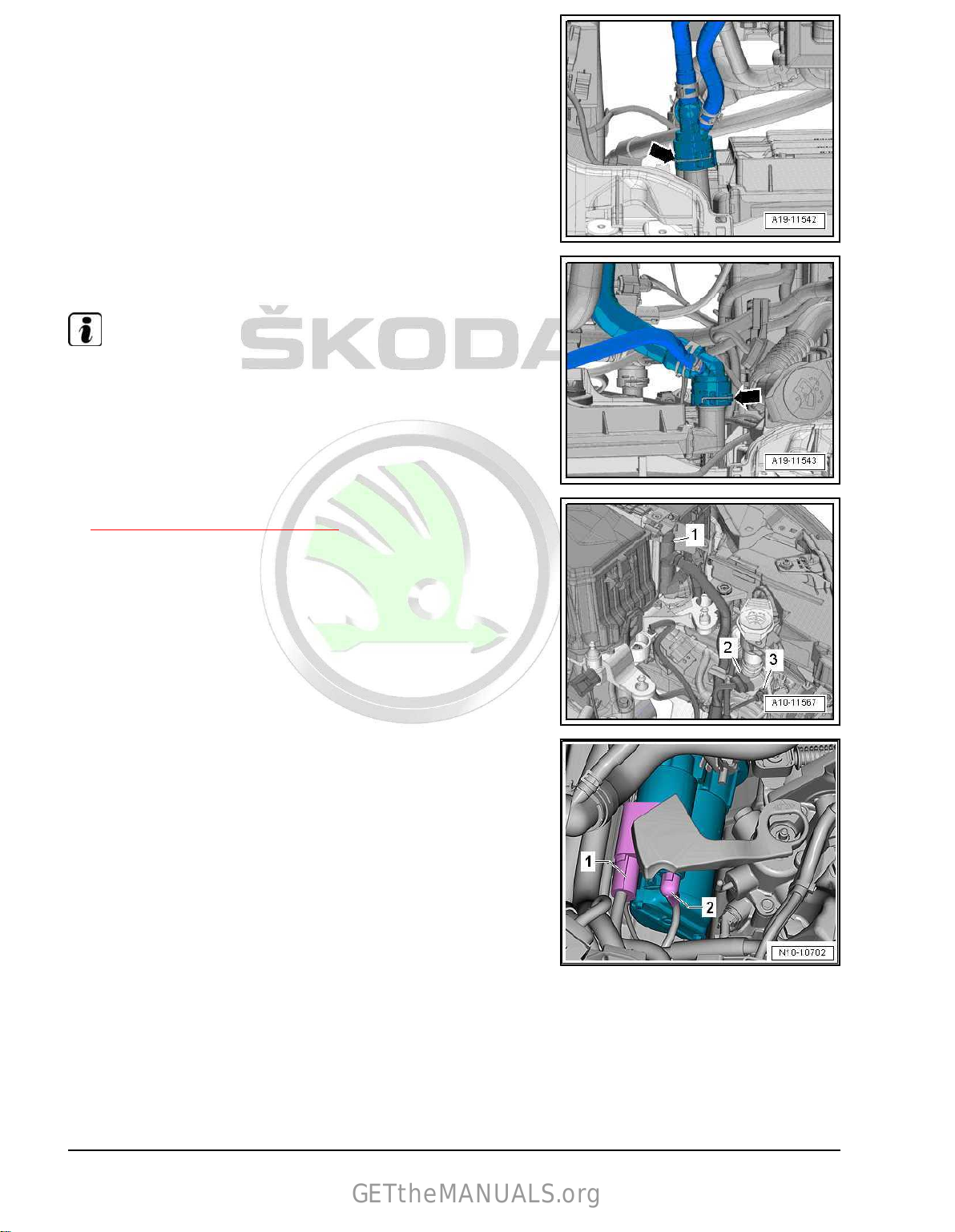

– Release screws -arrows- and remove holder.

Note

Place a cloth below to absorb leaking coolant.

– Loosen hose clamp -1- and remove coolant hose.

CAUTION

Risk of injury from fuel under pressure.

♦ To relieve the fuel pressure, place a clean cloth around the

connection point

and loosen the connection point carefully be‐

fore opening the fuel system.

NOTICE

Risk of malfunctions caused by soiling.

Observe safety measures and rules for cleanliness

⇒ “3.1 Cleanliness rules”, page 6 .

– Separate fuel feed line -1- and the line to activated charcoal

filter -2-.

– Loosen hose clamp -2- and remove coolant hose.

1. Removing and installing engine 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

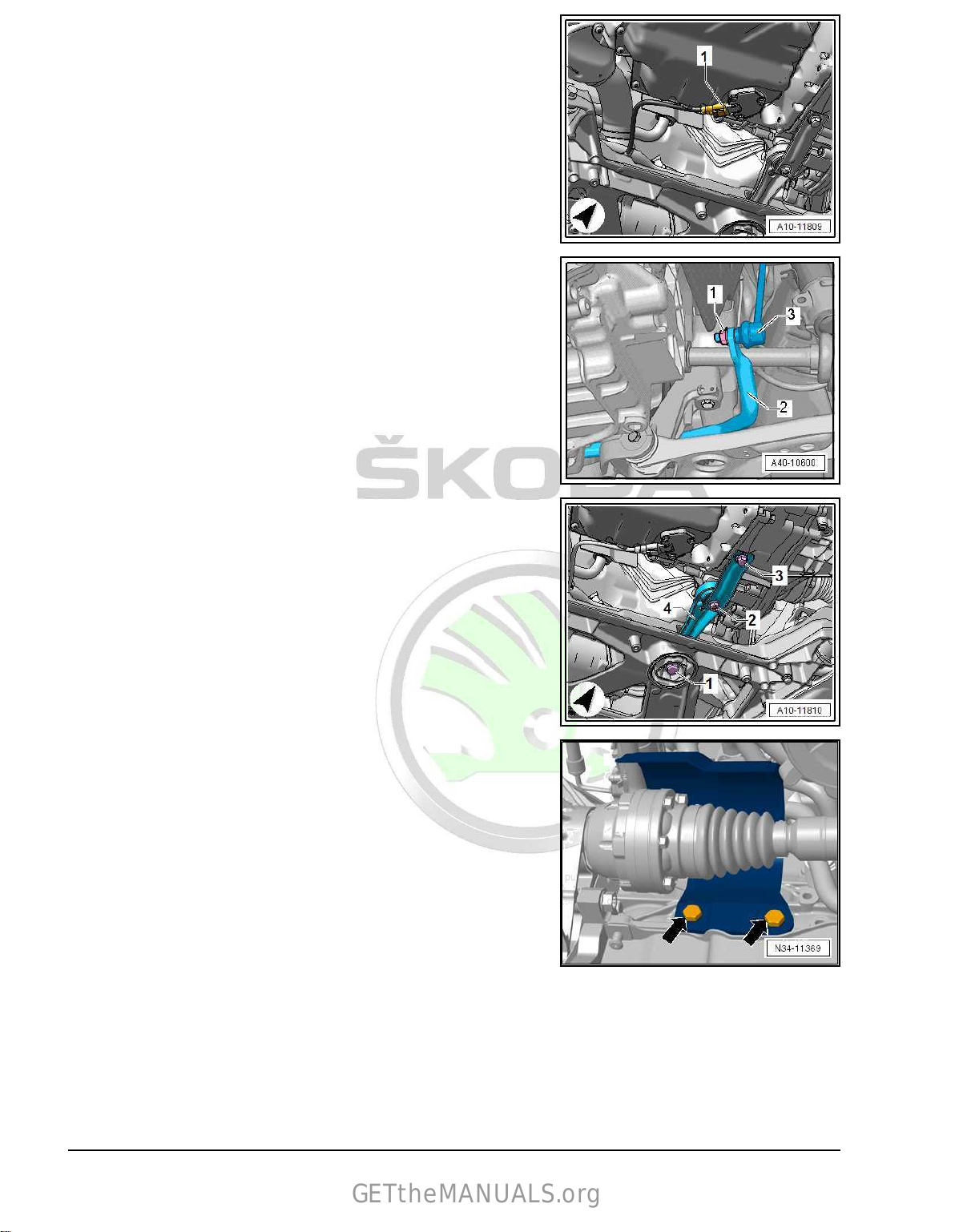

– Raise holding clamp -arrow- and disconnect coolant hose right

above radiator for charge air circuit.

– Raise holding clamp -arrow- and remove top left coolant hose

from radiator.

Note

For the following clip unclipping procedure use the removal tool

for inner door trim panel — MP8-602/1- .

– Unplug connector -1- on the engine control unit — J623-

⇒ “6 Engine control unit”, page 315 .

– Take electrical plug connections -2- and -3- out of the holder

and disconnect.

– Expose electric cables.

– Separate electrical plug connection -2-.

– Press back B+-pole protection -1- and unscrew B+-cable from

the starter magnet switch.

–

Unscrew the earth cable on the body.

14 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

– Unlock catches -arrows-, remove cover -1- for E-box in the

engine compartment.

– Unlock catch with a screwdriver -arrow- and pull cover -1- for

E-box in the engine compartment upwards.

– Unscrew nut -arrow-, remove and expose electric cable.

Vehicles fitted with a manual gearbox

– Disconnect plug connections -1- and -2-.

– Remove gearshift mechanism from the gearbox ⇒ Rep. gr.

34 ;

Gearshift mechanism; removing and installing shift mech‐

anism .

– Disconnect breather from slave cylinder ⇒ Rep. gr. 30 ; Clutch

mechanism; Removing and installing the breather .

Vehicles with automatic gearbox

– Remove selector lever linkage from gearbox, disconnect me‐

chatronics connector and remove all holders from the gearbox

⇒ Rep. gr. 37 ; Shift mechanism; installing and removing shift

mechanism .

– Disconnect plugs from mechatronics ⇒ Rep. gr. 34 ; Remov‐

ing and installing the gearbox; remove gearbox .

– Expose electric cable.

1. Removing and installing engine 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Continued for all vehicles

– Disconnect plug

— G266- .

– Unscrew nuts on left and right -1- for coupling rods -3- on anti-

roll bar -2-.

-1- at the oil level and oil temperature sender

– Undo screws -1-, -2-, -3- and remove the pendulum support

-4-.

– Release screws

dan shaft.

For vehicles with four-wheel drive

– Remove angle gearbox ⇒ Gearbox; Rep. gr. 34 ; Angle gear‐

box; Remove angle gearbox .

For Superb III vehicles with automatic gearbox

– Remove assembly carrier ⇒ Running gear, axles, steering;

Rep. gr. 40 ; Assembly carrier; Removing and installing as‐

sembly carrier with steering gear .

-arrows- and remove heat shield for right car‐

16 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

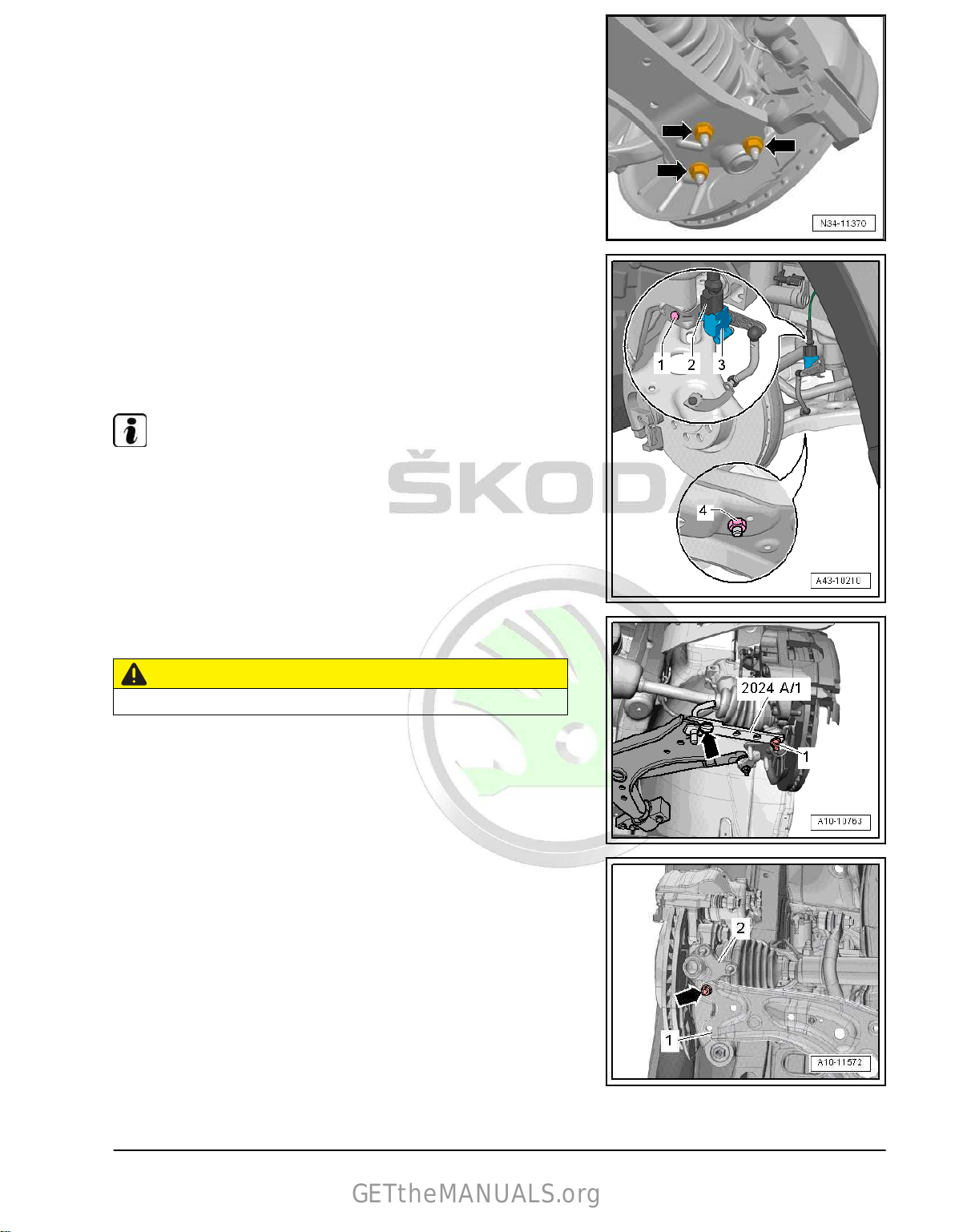

For Superb III vehicles with manual gearbox and for Kodiaq ve‐

hicles

– Unscrew nuts -arrows- on left and right for swivel hub.

– If present, unscrew nuts -4- and screw -1- from the front left

vehicle level sensor — G78- -3- and place to one side.

– Unhook swivel hub from track control arm on left and right for

swivel hub.

– Unscrew left and right cardan shaft from gearbox ⇒ Chassis,

axles, steering; Rep. gr. 40 ; Cardan shaft; removing and in‐

stalling cardan shaft and tie up.

Note

Ensure that the surface protection of the cardan shaft is not dam‐

aged.

– Swivel suspension strut left towards the outside and support

with extension -2024 A /1- , as shown in the illustration.

CAUTION

There is a risk of accident from loose parts of the support.

– Secure rig pin with plug-in lock and swivel hub-arrow- and

nut-1-.

– Screw swivel hub -2- right at the track control arm -1- tight

using the nut -arrow-, as shown in the illustration.

1. Removing and installing engine 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

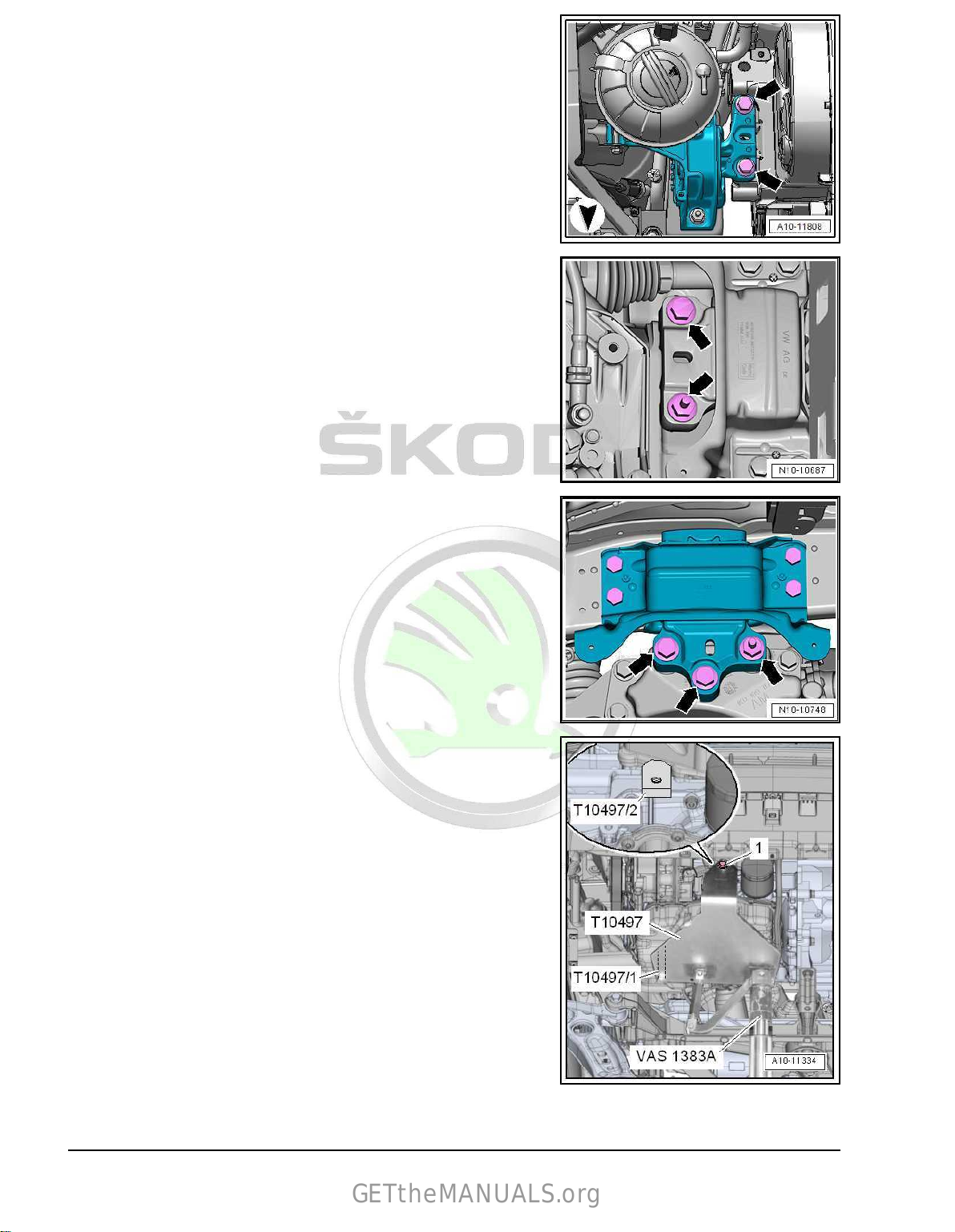

Continued for all vehicles

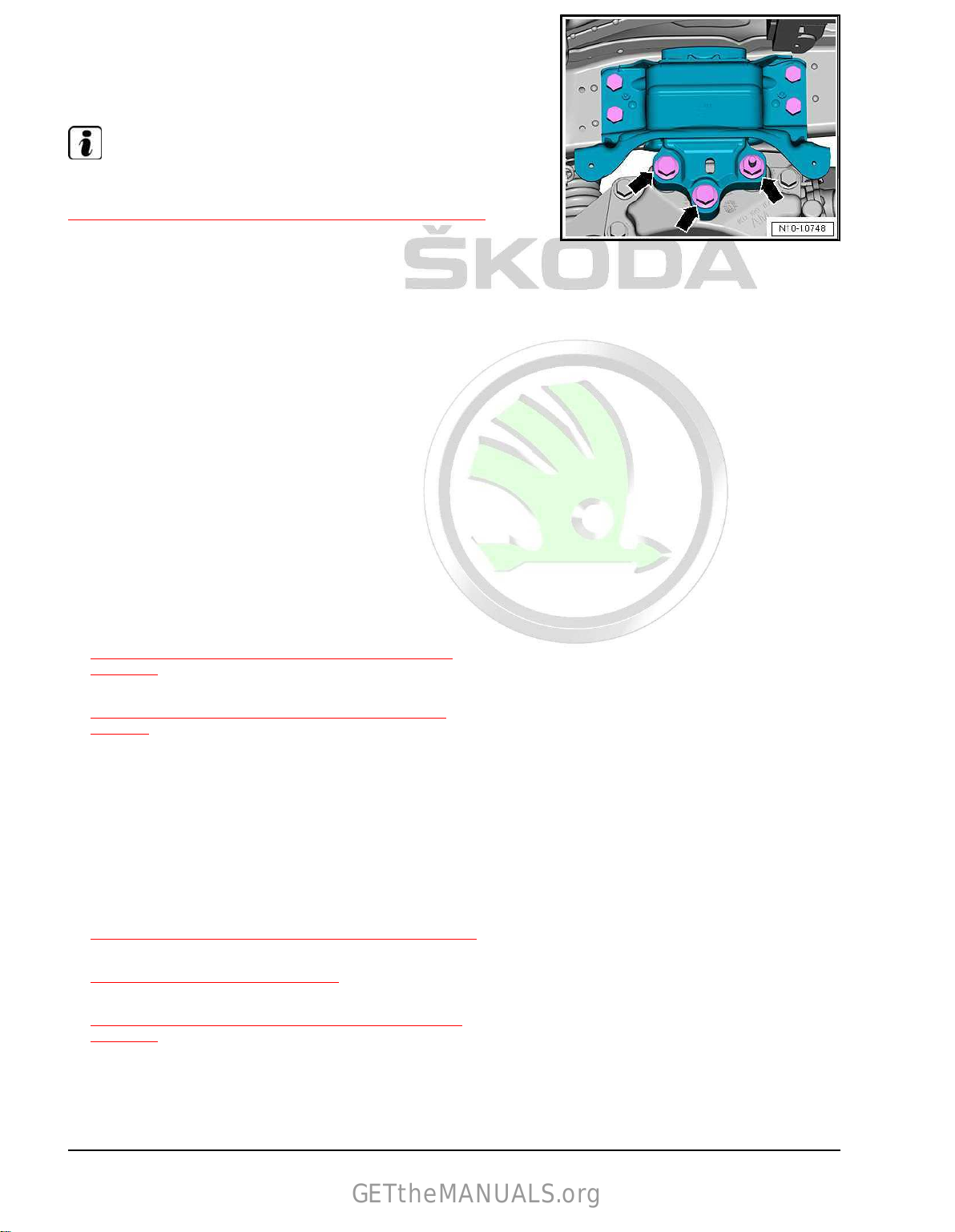

– Screw out screws -arrows- on engine mount by approximately

2 turns.

Gearbox mount with 2 screws

– Screw out screws -arrows- on gearbox mount by approxi‐

mately 2 turns.

Gearbox mount with 3 screws

– Screw out screws -arrows- on gearbox mount by approxi‐

mately 2 turns.

Continued for all vehicles

– Position clamping piece T10497A/2 on the housing fin of the

cylinder block, as shown in the illustration.

– Position

cylinder block.

– Screw clamping piece T10497A/2 with screw -1- onto the en‐

gine mount T10497A and tighten it to 20 Nm.

engine

mount — T10497A- with bolts T10497A/1 at the

18 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

– Fit the adapter — T10497A/3- to the engine mount — T10497A-

and tighten screw -1- to 20 Nm.

– Insert engine mount — T10497A- onto the engine and gearbox

jack

— V.A.G 1383A- or -VAS 6931- and lift the engine/gearbox

assembly a little.

Note

To remove the screws for the assembly mountings, use a com‐

mercially available double ladder , e. g. -VAS 5085- .

– Screw out engine mount screws -arrows- fully.

Gearbox mount with 2 screws

– Screw out gearbox mount screws -arrows- fully.

Gearbox mount with 3 screws

– Screw out gearbox mount screws -arrows- fully.

Continued for all vehicles

NOTICE

Risk of damaging vacuum lines or electric cables and the engine

compartment.

– Check that all vacuum lines and electric cables between en‐

gine, gearbox,

assembly mountings and body have been loos‐

ened.

– Drain engine/gearbox unit a little.

– Push the gearbox side of the engine/gearbox unit forwards

and drain it slowly and carefully.

1.2 Separate engine and gearbox

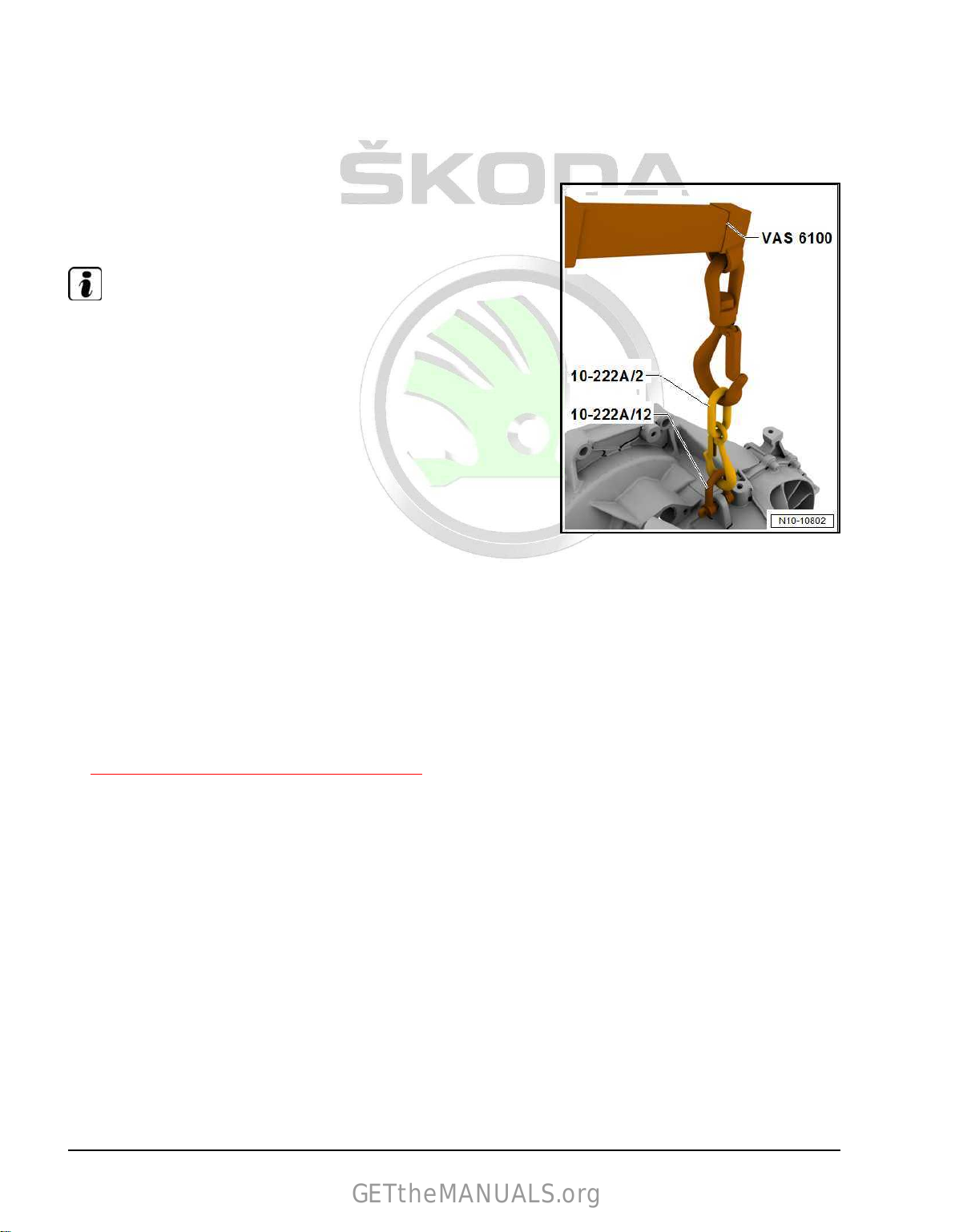

Special tools and workshop equipment required

♦ Additional hook — MP9-200/10 (10-222A/2)-

1. Removing and installing engine 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

♦ Workshop crane , e.g. -VAS 6100-

♦ Lifting eye — 10-222A/12Work procedure

• Engine/gearbox unit removed and attached to engine mount T10497A- .

– Remove starter ⇒ Electrical system; Rep. gr. 27 ; Starter;

Removing and installing starter .

– Install shackle — 10-222A/12- on gearbox.

– Hook additional hook — MP9-200/10 (10-222A/2)- with shackle

— 10-222A/12- onto the workshop crane — VAS 6100- .

Note

Pre-load the workshop crane — VAS 6100- slightly, but do not raise

the gearbox.

– Unscrew engine/gearbox connecting screws ⇒ Rep. gr. 34 ;

Removing and installing gearbox .

– Remove gearbox from engine.

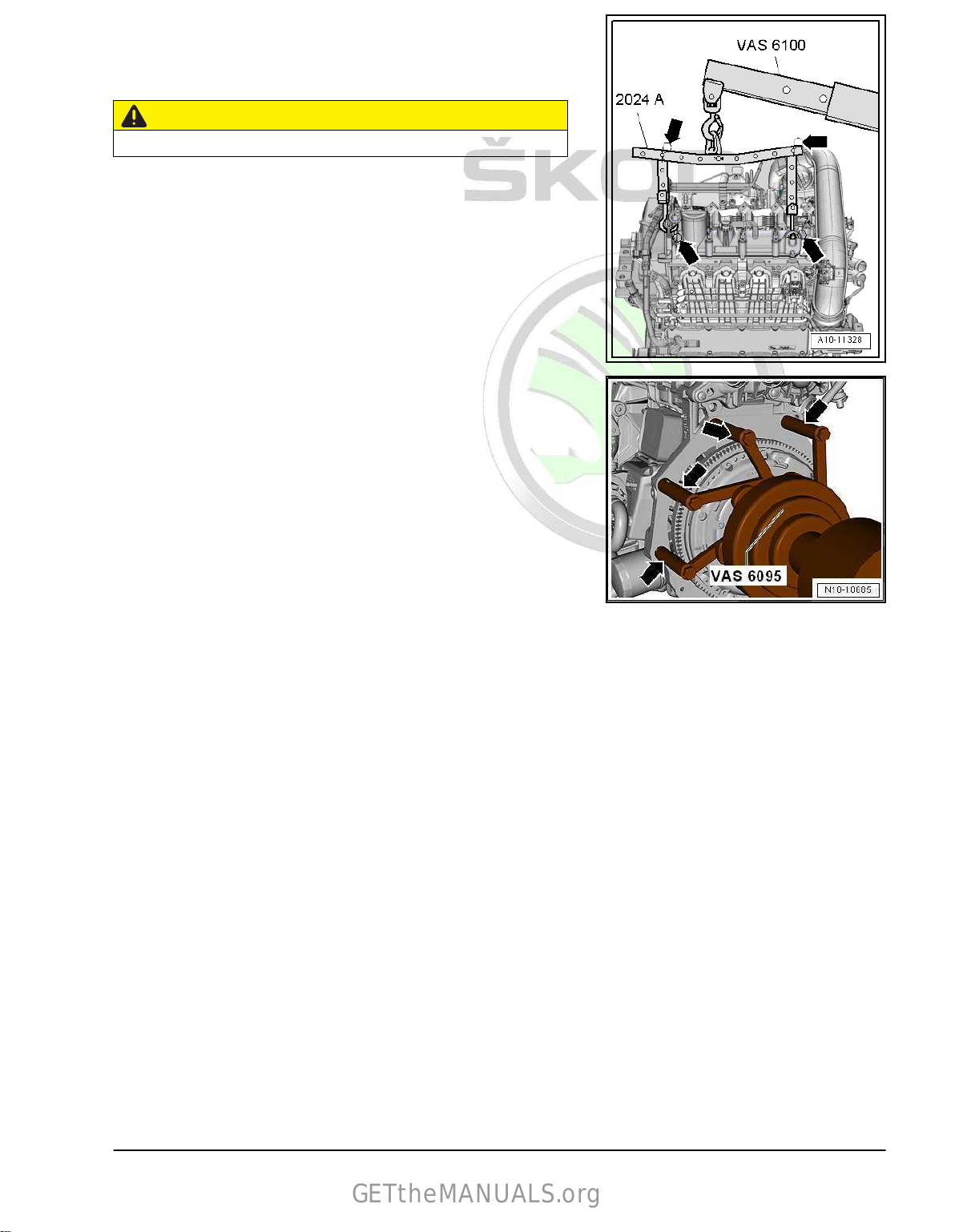

1.3 Attach engine attached to engine and

Special tools and workshop equipment required

♦ Supporting device — MP9-201 (2024A)♦ Engine and gearbox support — VAS 6095♦ Workshop crane , e.g. -VAS 6100Work procedure

• Gearbox disconnected from engine

⇒ “1.2 Separate engine and gearbox”, page 19 .

gearbox mount

20 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

– Suspend lifting device — MP9-201 (2024A)- from the engine

and workshop

crane — VAS 6100- as shown in the illustration.

– For coordination with the unit centre of gravity position the

perforated rails must be placed as shown in the illustration.

CAUTION

There is a risk of accident from loose parts of the lifting device.

– The suspension hooks and rig pin on the lifting must be se‐

cured using plug-in locks -arrows-.

–

Lift engine with installed engine mount T10497A off the en‐

gine/gearbox jack — V.A.G 1383 A- with workshop crane VAS 6100- .

– Remove engine mount T10497A .

– Secure engine with bolts -arrows- at engine and gearbox

mount — VAS 6095- as shown in the illustration.

1.4 Installing engine

Special tools and workshop equipment required

♦ Extension — 2024 A /1- of lifting device — MP9-201 (2024A)♦ Engine and gearbox jack , e.g. -V.A.G 1383A- or -VAS 6931♦ Engine mount — T10497A♦ Hose strap pliers , e.g. -VAS 6362♦ Locking pin — T10060A♦ Double ladder , e. g. -VAS 5085♦ Protective goggles and gloves

♦ Grease — G 000 100For vehicles with manual gearbox

– Clean the serration of the drive shaft and if the clutch disc has

been used clean the hub serration, remove any corrosion

present

to the serration of the drive shaft.

– Subsequently move the clutch disc up and down on the drive

shaft until the hub fits smoothly on the shaft. Always remove

excess grease.

– Check centring of driven plate assembly ⇒ Rep. gr. 30 ;

Clutch; removing and installing clutch .

and only apply a very thin layer of grease — G 000 100-

1. Removing and installing engine 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

– Check the clutch release bearing for wear. Replace release

bearing when

of components- Clutch release mechanism .

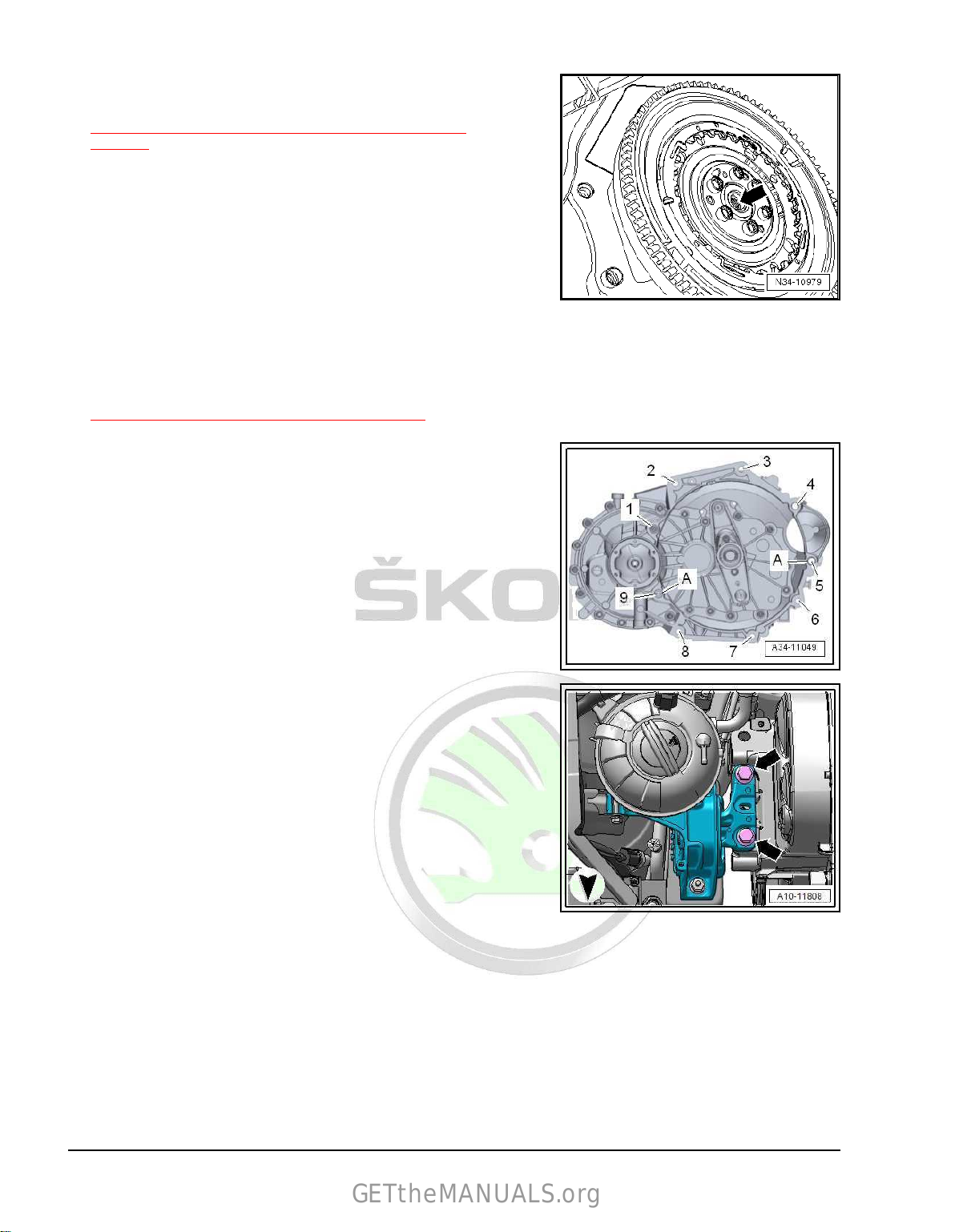

For vehicles with automatic gearbox

– Replace the needle bearing in the crankshaft

⇒ “3.2 Replace the needle bearing in the crankshaft”,

page 63 .

Continued for all vehicles

Installation is performed in the reverse order, pay attention to the

following points:

– Screws which have been tightened firmly to a torquing angle

must be replaced.

– Replace self-locking nuts, gasket rings, gaskets and O-rings.

• Secure all hose connection ends with spring-type clips that

comply with

of Original Parts .

• Fit all cable straps on again in the same place when installing.

– Installing intermediate plate

⇒ Fig. ““Installing intermediate plate”“ , page 53 .

– If there are no dowel sleeves in the cylinder block for centering

the engine and gearbox, insert dowel sleeves

– Screw gearbox securely onto engine at positions -1-, -2-, -3-,

-6-, -7-, -8- and -9-.

– Install gearbox support bracket.

– Attach engine/gearbox unit to engine mount — T10497A- .

– Insert engine/gearbox unit into the body.

worn ⇒ Rep. gr. 30 ; Clutch control; Summary

the series design ⇒ ETKA — Electronic Catalogue

-A-.

– Initially insert screws -arrows- for engine mount by hand as far

as the stop.

22 Rep. gr.10 — Removing and installing engine

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Gearbox mount with 2 screws

– Initially insert screws -arrows- for gearbox mount by hand as

far as the stop.

1. Removing and installing engine 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Gearbox mount with 3 screws

– Initially insert screws -arrows- for gearbox mount by hand as

far as the stop.

Continued for all vehicles

Note

The screws must not be permanently tightened until the assembly

bracket is adjusted

⇒ “2.1 Assembly overview — assembly mountings”, page 26 .

– Remove engine mount — T10497A- from engine.

Vehicles fitted with a manual gearbox

– Connect breather to slave cylinder ⇒ Rep. gr. 30 ; Clutch

mechanism; Removing and installing the breather .

– Install linkages with cable support ⇒ Rep. gr. 34 ; Shift mech‐

anism; installing and removing shift mechanism .

Vehicles with automatic gearbox

– Install assembly carrier ⇒ Running gear, axles, steering; Rep.

gr. 40 ; Assembly carrier; Removing and installing assembly

carrier with steering box .

– Install selector lever linkage, install mechatronics connector

and install holders to the gearbox ⇒ Rep. gr. 37 ; Shift mech‐

anism; installing and removing shift mechanism .

For vehicles with four-wheel drive

– Install angle gearbox ⇒ Gearbox; Rep. gr. 34 ; Angle gearbox;

Remove angle gearbox .

Continued for all vehicles

– Install exhaust pipe with catalytic converter

⇒ “2.2 Removing and installing catalytic converter”,

page 354 .

– Install pendulum support

⇒ “2.1 Assembly overview — assembly mountings”,

page 26 .

– Install drive shafts ⇒ Running gear, axles, steering; Rep. gr.

40 ; Drive shaft; Removing and installing drive shaft .

– Install track control arm, steering joint and coupling rod ⇒

Chassis, Axles, steering; Rep. gr. 40 ; Bottom track control

arm, steering joint; Removing and installing the bottom track

control arm .

– Install AC compressor ⇒ Heating, Air Conditioning; Rep. gr.

– Install the V-ribbed belt

– Connect plug for engine control unit — J623-

– Connect coolant hoses with quick coupling

– Install the front left and right wheelhouse liner⇒ Exterior body

AC compressor; Removing and installing AC compressor .

87 ;

⇒ “1.3 Removing and installing V-ribbed belt”, page 41 .

⇒ “6 Engine control unit”, page 315 .

⇒ Fig. ““Connect coolant hose with quick coupling”“ ,

page 253 .

Rep. gr. 66 ; Wheelhouse liner; Removing and installing

work;

the front wheelhouse liner .

24 Rep. gr.10 — Removing and installing engine

Loading…